Reaction Bonded Silicon Carbide(SiSiC) Ceramics

Reaction Bonded Silicon Carbide(SiSiC) Ceramics products are main characteristics like corrosion resistance, high temperature resistance,anti-oxidation, Low porosity, high surface accuracy, High thermal conductivity, wear resistance, high strength and loading carrying Capacity,keeping shape after long term use,high strength long service life and light weight, easy to make a variety of shapes,good smoothness and not easy to plug.

Si-SiC ceramic customization as your request

We can design excellent Si-SiC ceramics as your request.Our manufacturing enterprises passed through the ISO9001:2000 international quality management system certification.

Our technicians have more than ten years of research and production experience in silicon carbide products.

Our products get excellent reports from SGS, BV, Intertek.

Our vision is to dedicate you the most professional silicon carbide ceramic products.

SiSiC Technical Parameter Physical and chemical indexes

Application Temperature: ≦1380℃; Density: ≧3.02g/cm3; Open Porosity: <0.1%; Bending Strength: 250(20℃) Mpa\280(1200℃) Mpa;Modulus of elasticity: 330(20℃) Gpa\300(1200℃) Gpa; Thermal Conductivity: 45(1200℃) W/m.k; Coefficient of thermal expansion: 45 K-1x10-6;

Meh’s Scale of Hardness: 13; Acid Alkaline-Proof: Excellent.

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

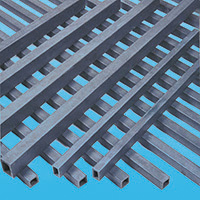

Si-SiC Kiln Furniture

-

Si-SiC Cross Beams

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC Properties high temperature resistance and loading carrying Capacity,

high strength and keeping shape after long term use, anti-oxidationUsage The load bearing for domestic ceramics

and electro-ceramics in tunnel kiln and shuttle kilnSiSiC Beams are featured with high temperature resistance and loading carrying Capacity, anti-oxidation, high strength and keeping shape after long term use. They sever as the load bearing for domestic ceramics and electro-ceramics in tunnel kiln and shuttle kiln.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent Specification indexes Item Size/mm 1 40*40*2700*6 2 40*40*2400*6 3 40*40*2100*6 4 40*40*1900*6 5 40*40*1700*6 6 40*40*1480*6 7 40*60*2350*8 8 40*40*2000*8 9 30*30*2700*5 10 30*30*2400*5 11 30*30*1700*5 12 30*30*2100*5 13 30*30*1900*5 Other specs can be supplied as clients' request -

Si-SiC Rollers

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC Properties good seismic performance and anti-oxidation

with no fracture after long term useUsage domestic ceramics, sanitary,

architectural ceramics and glass in roller kilnSiSiC rollers have the advantages of good seismic performance and anti-oxidation with no fracture after long term use. They are the ideal material for domestic ceramics, sanitary, architectural ceramics and glass in roller kiln.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent Specification indexes Item Size/mm 1 D18.8*2075*7 2 D40*1500*6 3 D50*1700*6 4 D40*2100*6 5 D40*1700*6 6 D30*1900*5 7 D100*1190 8 D130*1190 9 D48*1247 10 D25*2470*9 Other specs can be supplied as clients' request

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

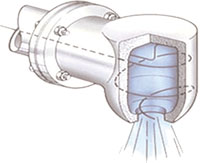

Si-SiC Burner Nozzles

-

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC,Spray Nozzle Properties effective to control furnace temperature Usage kiln furniture in tunnel kiln, shuttle kiln and other industrial kilns, also in open flame heating and radiation tube heating system in industrial furnace SiSiC spouts are the ideal kiln furniture in tunnel kiln, shuttle kiln and other industrial kilns, which are effective to control furnace temperature. They are also widely used in open flame heating and radiation tube heating system in industrial furnace.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent -

← SiSiC Burner Nozzles Application

Specification indexes Item Size/mm 1 Z001 Φ86*460 2 Z002 Φ265*430 3 Z003 Φ80*550 4 Z004 Φ90*550 5 Φ94*460 6 Φ94*660 Other specs can be supplied as clients' request

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

Si-SiC Radiation Pipes

-

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC Properties anti-high temperature, good thermal conductivity,

anti-oxidation, anti thermal shock performance and long service lifeUsage heat conduction and dissipation devices under high temperature and high corrosion situations SiSiC radiation pipes are characterized with anti-high temperature, good thermal conductivity, anti-oxidation, anti thermal shock performance and long service life, which are applied in heat conduction and dissipation devices under high temperature and high corrosion situations.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

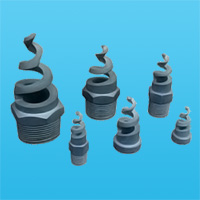

Si-SiC Nozzles

-

Si-SiC Vortex Nozzles

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC,Spray Nozzle Properties corrosion resistance, high surface accuracy, wear resistance, high strength and anti-oxidation, long service life and light weight,easy to make a variety of shapes Usage key components of gas desulfurization and dust removal device in thermal power plants and large boilers SiSiC desulfurization nozzles are key components of gas desulfurization and dust removal device in thermal power plants and large boilers, which are used in bulk in those devices.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent Specification indexes Item Size 1 3" 2 4" 3 3" Thickened 4 2"(Outlet angel 90°) 5 2.5"(Outlet angel 90°)Thickened 6 2.5"(Outlet angel 90°) 7 2.5"(Outlet angel 120°) Other specs can be supplied as clients' request

← SiSiC desulfurization nozzles Application

-

Si-SiC Spiral Nozzles

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC Properties corrosion resistance, high surface accuracy, wear resistance, high strength and anti-oxidation, long service life and light weight,easy to make a variety of shapes, good smoothness and high temperature resistance(1400℃ below). Usage key components of gas desulfurization and dust removal device in thermal power plants and large boilers SiSiC Spiral nozzles bear the main features like corrosion resistance, high surface accuracy, wear resistance, high strength and anti-oxidation, long service life and light weight. They are easy to make a variety of shapes and not easy to plug with good smoothness and high temperature resistance(1400℃ below).

← SiSiC Spiral nozzles Application

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

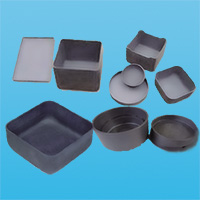

Si-SiC Saggers and Crucibles

-

Material Silicon Carbide, Reaction bonded Silicon Carbide, RBSiC, SiSiC Properties corrosion resistance, wear resistance, high strength

and anti-oxidation, long service life and light weight.Usage in metallurgy, chemicals, glass industrial furnace SiSiC crucibles and saggers are suitable to be used in industrial furnaces for the production of powder sintering in metallurgy, chemicals, glass industries.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

Si-SiC Tube Liner

-

Si-SiC Tube Liner with high strength,high wear resistantce is widely used in papermaking, chemical, electronics, pharmaceutical and other ink jet, lithium battery materials, electronic pulp nano-ceramic sanding machines.

Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

Si-SiC Grinding Barrel

-

Si-SiC Grinding Barrel is used as lining of sand mill.

It has 5 times life time of normal wear-resistant material.Characteristics of silicon carbide wear-resistant barrel:

1. very low abrasion, can prevent the material pollution.

2. suitable for all kinds of grinding and dispersing occasions.

3. high grinding efficiency.

4. a very long service life, low cost of integrated operation.Physical and chemical indexes Application Temperature ≦1380℃ Density ≧3.02g/cm3 Open Porosity <0.1% Bending Strength 250(20℃) Mpa

280(1200℃) MpaModulus of elasticity 330(20℃) Gpa

300(1200℃) GpaThermal Conductivity 45(1200℃) W/m.k Coefficient of thermal expansion 45 K-1x10-6 Meh’s Scale of Hardness 13 Acid Alkaline-Proof Excellent -

Used in Sand Mill ↓

-

Our products get excellent reports from SGS, BV, Intertek ↓