Pressureless sintering Silicon Carbide Products(S-SiC)

SSIC ceramic was made from high purity and ultra-fine silicon carbide powder with a small quantity of sintering aids. Under inert gas or vacuum atmosphere of barometric pressure, these materials were sintering under high temperature 1950~2100℃, the ceramics products with excellent mechanical properties (smooth, wear-resisting, etc.) and chemical properties (stable, strong corrosion resistance, etc.) were almost completely dense. Differed from SISIC, SSIC ceramics do not contain free silicon and metal adhesives which are vulnerable to corrosion, and it has achieved excellent performance in strong acid and alkali environment as it was formed by uniform and dense SiC. Independent and discontinuous spherical pores(50±μm) which putting on sliding interface of SSiC sealing article, can be used as fluid or storage of lubricants on the surface of sliding elements. It can promote the sliding interface to keep the fluid-flim bearing, which improves the friction performance of SSiC products.

Extremely strong corrosion resistance and excellent frictional characteristic makes SSiC to be a wise choice of application of industrial sealing surface. It can be applied in the field of chemical processing, petroleum refining, waste water, paper and pulp, mining, nuke industry, ocean, household appliances and so on.

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

S-SiC Mechanical Components

-

Design as your request

S-SiC Mechanical components SiC 99% min Density 3.12g/cm3 min or 3.04g/cm3 Open Porosity 1%max or 4.0-6.0% Bending Strength 440(1700℃)MPa Compressive Strength 2400(1700℃)MPa Coefficient of Thermal Expansion 4.2 K-1x10-6 Thermal Conductivity 60W/m.k(1700℃) Application temp 1600-1700℃ max -

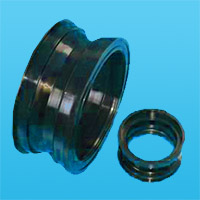

S-SiC Sealing Ring、SSiC Automobile Water Pump Ring、SSiC flat ring ↓

Sealing Rings Types Reaction

Bonded SiCPressureless Sintering SiC Hot Pressed

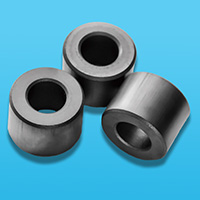

Sintering SiCSpecs SiSiC SSiC HPSiC SSiC-A SSiC-B SSiC-C Density g/cm3 >3.03 >3.08 >3.20 2.65-2.95 >3.15 Hardness HV0.5 / >2200 >2200 / >2500 HRA >90 >92 >92 / >93 HS / / / >85 / Bending strength Mpa >350 >400 >500 >150 >550 Compressive strength Mpa >2000 >2000 >2200 >1500 >2200 Elastic modulus Gpa 350 400 420 120 420 Thermal expansion coefficient 10-6/℃ 4.0 4.0 4.2 3.0 4.0 Thermal conductivity W/m·k 50-100 90-100 60 120 120 Free silicon content % <12 - SiC purity % >98 Component SiC Si C SiC B4C C SiC YAG SiC C SiC B4C C S-SiC Bushing、Cone Bushing ↓

-

← Si-SiC Rollers

Special Design for you as your request

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

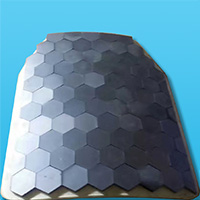

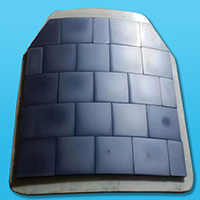

S-SiC Bullet Proof Ceramics

-

S-SiC bullet proof ceramics/td> SiC 99% min Density 3.12g/cm3 min Bending Strength 420MPa Compressive Strength 2200-2300MPa Vickers-hardness 2650 Modulus of Elasticity 420Gpa SiC bullet proof ceramics have the advantages of high-hardness, good absorbing capacity, light-weight, excellent ballistics performance, high-temperature resistance. It is the idea materials to produce the body armor, bulletproof armors for vehicles, ships, helicopters and so on.

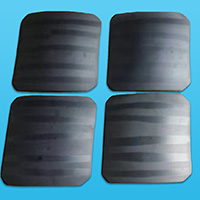

S-SiC Bullet Proof and bulletproof Column ↓

-

S-SiC Bulletproof ↓