Si3N4 bonded SiC Products

Si3N4 bonded SiC is a new type of high-grade refractory materials. Its products mainly include radiant tube, brick, deformed parts and so on. These products, which maintains energy saving, environmental protection, high temperature resistance, corrosion resistance and other advantages, can be widely applied in the field of steel, non-ferrous mental, chemical construction materials, etc.

Performance

1. Si3N4 bonded SiC: hard texure, about Moh’s hardness 9, be next only to diamond, belongs to hard material in the field of nonmetallic material.

2. Si3N4 bonded SiC products with high strength in normal temperature. Under 1200-1400℃, it can keeps almost same strength and hardness with it under normal temperature. As the environment is different, the maximum service temperature can reached up to 1650-1750℃.

3. Small thermal expansion. Compared with SiC products,which are with high thermal conductivity and difficult to produce thermal stress, it maintains good thermal shock resistance, long service life. It can be easily to be made into products with high dimensional accuracy since its advantages such as strong creep-resistance in high temperature, corrosion resistance, extremely cold or hot resistance, and antioxidant.

| Physical & Chemical Index | ||||

| Physical Index | Volume Density (g/cm2) |

Apparent Porosity(%) | Compression Strength under Normal Temperature (MPa) |

Rupture Strength under Normal Temperature(MPa) |

| ≥2.65 | ≤10.7 | ≥170 | ≥30 | |

| Chemical Index(%) | SiC | Si3N4 | Fe2O3 | FSi |

| ≥60 | ≥37 | ≤1.5 | ≤1.0 | |

Application :

Widely applied in Steel industry, non-ferrous metal industry, chemical construction materials and other industries. It have advantages in energy saving, environmental protection, cost reduction.SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

Si3N4-SiC Pump

-

HVT Serial SiC Slurry Pump

HVT Serial SiC Slurry Pump Quantity of Flow Q 800~14000m3/h Pump Lift H 15~44m Outlet Diameter 300-1500mm Application Transfer acids or alkalis corrosive slurry,

fluid with abradability or scale formationMaterials CD4MCu、Cr30、2507、SiC、Hastelloy、20# Advantage The pump parts which contact with fluid medium

are made by SiC, which can give play to wear-resistance and corrosion-resistance of SiC, and also guarantee the whole strength and toughness of pump. -

ZV Serial SiC Slurry Pump

ZV Serial SiC Slurry Pump Quantity of Flow Q 5~2500m3/h Pump Lift H 9~135m Outlet Diameter 50-300mm Application Transport abrasive and corrosive slurry which containing particulate: ore pulp in metallurgy dressing plant、ash and coal slurry in power plant、coal slurry and dense medium in coal wahsery; etc. Materials Cr26、Cr33、Cr15Mo3、SiC Advantage The service life is long, and the maintenance times are greatly reduced. -

Pump Parts:SiC Pump body、SiC Enclosed Impeller、SiC Open Impeller ↓

-

← SiC Circulating Pump Impeller

SiC Powder

Green SiC Powder

Black SiC Powder

Si-SiC

Si-SiC Kiln Furniture

Si-SiC Burner Nozzle

S-SiC

S-SiC Mechanical Componen

S-SiC Bullet Proof Ceramics

Si3N4-SiC

Si3N4-SiC Bricks for Waste Incineration

Si3N4-SiC Pump

Electroplated Diamond Wire Saw

For Cutting Solar Wafers

For Root Solar Silicon Body

For Cutting Crystal Sapphire

for Cutting Magnetic Materia

Si3N4-SiC Products

-

Si3N4-SiC bricks for Waste Incineration

Item Value Bulk Density ≧2.65g/cm3 Apparent porosity ≦15% Compressive strength ≧150MPa Rupture strength at r. t. ≧40MPa SiC ≧75% Si3N4+Si2N2O ≧15% -

Si3N4-SiC Kiln Furniture

Physical and chemical indexes SiC ≥72% Si3N4 ≥22% Fe2O3 ≤0.7% Si ≤0.4% Bulk Density ≥2.65g/cm3 Apparent Porosity <16% Compressive Strength r. t. ≥170MPa Modulus of Rupture ≥45MPa(r. t.) ≥50MPa(1400℃) Thermal Conductivity ≥15w/m.k(1100℃) Refractoriness 1800℃ Max Working Temperature 1550℃ Other specs can be supplied as clients' request. -

Si3N4-SiC Protection Tube

Applications: metal casting, molten metal industry

Features and Advantages

1. It quickly improves temperature of metal liquid, with good conductivity of 16-18 w/m.k (1100℃). The sheath wall is thin to 15-20mm.

2. It won't be melted or eroded by metal liquid, and will not contaminate the liquid.

3. It is designed in simple structure, easy to install and maintain.

4. It works well when immersed in metal liquid even the temperature is such high, and can work for long time.

5. It is easy to install while using, and easy to maintainItem Result Item Result density(g/cm3) 2.72-2.80 SiC(%) 73-75 apparent porosity(%) 11-13 Si3N4(%) 22-24 normal temperature Rupture (MPa) 40-55 SiO2(%) 1-3 high temperature Rupture (MPa) 50-65 Si(%) <0.5 heat conductivity (w/m.k)(1100℃) 16-18 the highest working temperature(℃) 1600 heat expansion(×10-6) 4.2 Material: silicon nitride bonded silicon carbide (N-SiC)

Working Temperature: < 1600℃ -

Desulfurizing Nozzle(FGD Nozzle) Si3N4-SiC Nozzle

Silicon nitride bonded silicon carbide nozzle is mainly used in Fuel Gas Desulfurization (FGD) system. As one component of FGD system, the nozzle can spray out lime slurry in certain flow-rate, angle and granularity, for the slurry to completely react with gases such as HF, SO2, NO2 which comes from burning boiler. After FGD reaction, the generated plaster can be recycled for construction, while the clean gas will be discharged directly to atmosphere. That’s for environmental protection.

Applications: used in flue gas desulfurization- environmental protection in coal power and other coal-fired fields.

Features and Advantages

1. It is featured with reasonable granularity, angle, and flow-rate. It can be customized, to meet customer’s requirement, and the performance is reliable.

2. It shows good performance of abrasion resistance, corrosion resistance, and long life-time. The longest working hours can reach 80,000-100,000 h.

3. It is designed in simple structure, easy to install and maintain.Si3N4-SiC Nozzle Mouths ↓

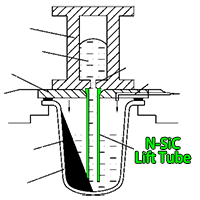

Si3N4-SiC Lift Tube

Material: Silicon Nitride bonded Silicon Carbide

Applications: widely used in nonferrous metal casting area, especially low pressure casting for aluminum alloy wheel.

Features and Advantages:

1. Anti-melting and anti-corrosion, no contamination to metal liquid.

2. Good at thermal shock resistance, no dreg or crack.

3. Airproof, no aluminum adhered, no slag accumulated, preventing air hole on casting piece.

4. Easy maintenance, long life-time, cost-effective.

Si3N4-SiC Degassing Rotor

Application: mainly used in nonferrous metal casting –aluminum degassing.

Features and Advantages

1. Rotor and shaft are both made of silicon nitride bonded silicon carbide material, which shows advantage in anti-oxidation and anti-corrosion compared with graphite one. Within life span, degassing effect keeps stably good.

2. High-speed rotation can maximumly crush air bubble, and maximumly drive air bubble to cavity corner, improving degassing efficiency.

3. Rotor and shaft are anti-melting and anti-corrosion, no contamination to metal liquid.

4. It owns smooth surfacea and there will be no aluminum adhering or dreg accumulating. The concentricity is controlled within 1mm, which ensures smooth and peaceful rotation.

5. It cuts down the cost of degassing, such as inert gas consumption, grilled slag aluminum wastage, improving reliability of equipment and reduce cost of maintenance.

Si3N4-SiC Brick for Aluminum Electric Tank

Applications: Mainly used in alumina electric tank.

Features and Advantages

1. Ware resistance, thermal shock resistance, and high temperature structural and high resistivity to alkalis.

2. It can reduce 15% power consumption.

3. Any size and shape can be supplied as your request.

Si3N4 Bonded SiC Kiln Furniture SiC ≥71% Si3N4 ≥23% Fe2O3 ≤1.0% Si ≤0.4% Bulk Density ≥2.65g/cm3 Apparent Porosity <16% Compressive Strength r. t. ≥160MPa Modulusof Rupture ≥45MPa(r. t.) ≥50MPa(1400℃) Thermal Conductivity ≥15w/m.k(1100℃) Refractoriness 1800℃ Max Working Temperature 1550℃ Other specs can be supplied as clients' request

Si3N4-SiC Brick for Abdomen of Blast Furnace-A

Applications: Mainly used in blast furnace lining, and various nonferrous metal smelting, glass tank and ceramic industries, etc.

Features and Advantages

1. Its usage life is 6 times of clayey bricks, and 2.5 times of high aluminum brick.

2. Ware resistance, thermal shock resistance, and high temperature structural and high resistivity to alkalis.

3. Any size and shape can be supplied as your request.Si3N4 Bonded SiC Kiln Furniture SiC ≥71% Si3N4 ≥23% Fe2O3 ≤1.0% Si ≤0.4% Bulk Density ≥2.65g/cm3 Apparent Porosity <16% Compressive Strength r. t. ≥160MPa Modulus of Rupture ≥45MPa(r. t.) ≥50MPa(1400℃) Thermal Conductivity ≥15w/m.k(1100℃) Refractoriness 1800℃ Max Working Temperature 1550℃ Other specs can be supplied as clients' request. -

Si3N4-SiC Irregular Products

Special Design for you as your request

Analysis Room and Workshop Partial photos ↓